Nora Kurth

Manufacturing Methods

Preparation for the final project

After being given a theoretical overview of the manufacturing method of masterforming for two sessions of the course, it was time for more practical things.

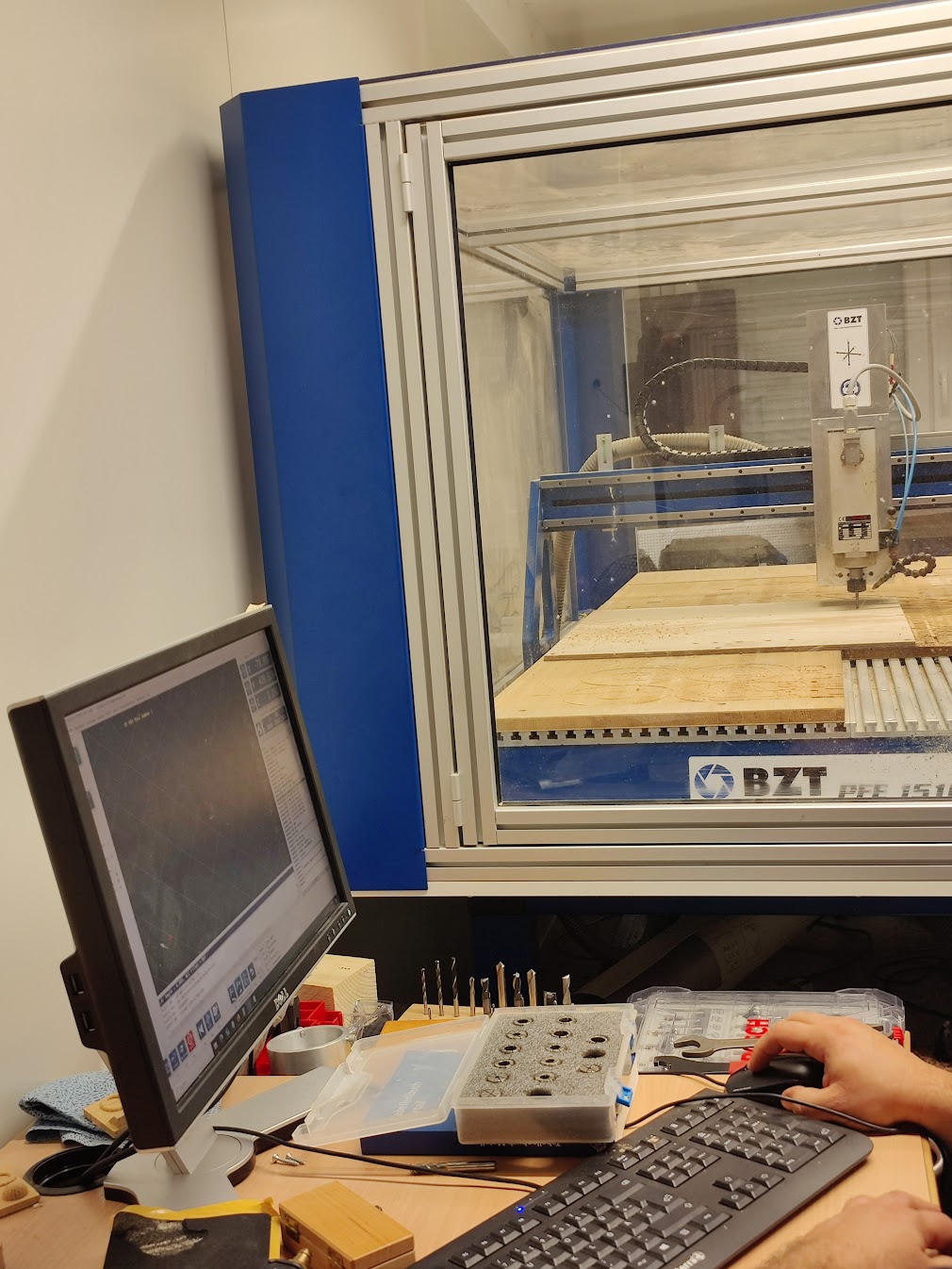

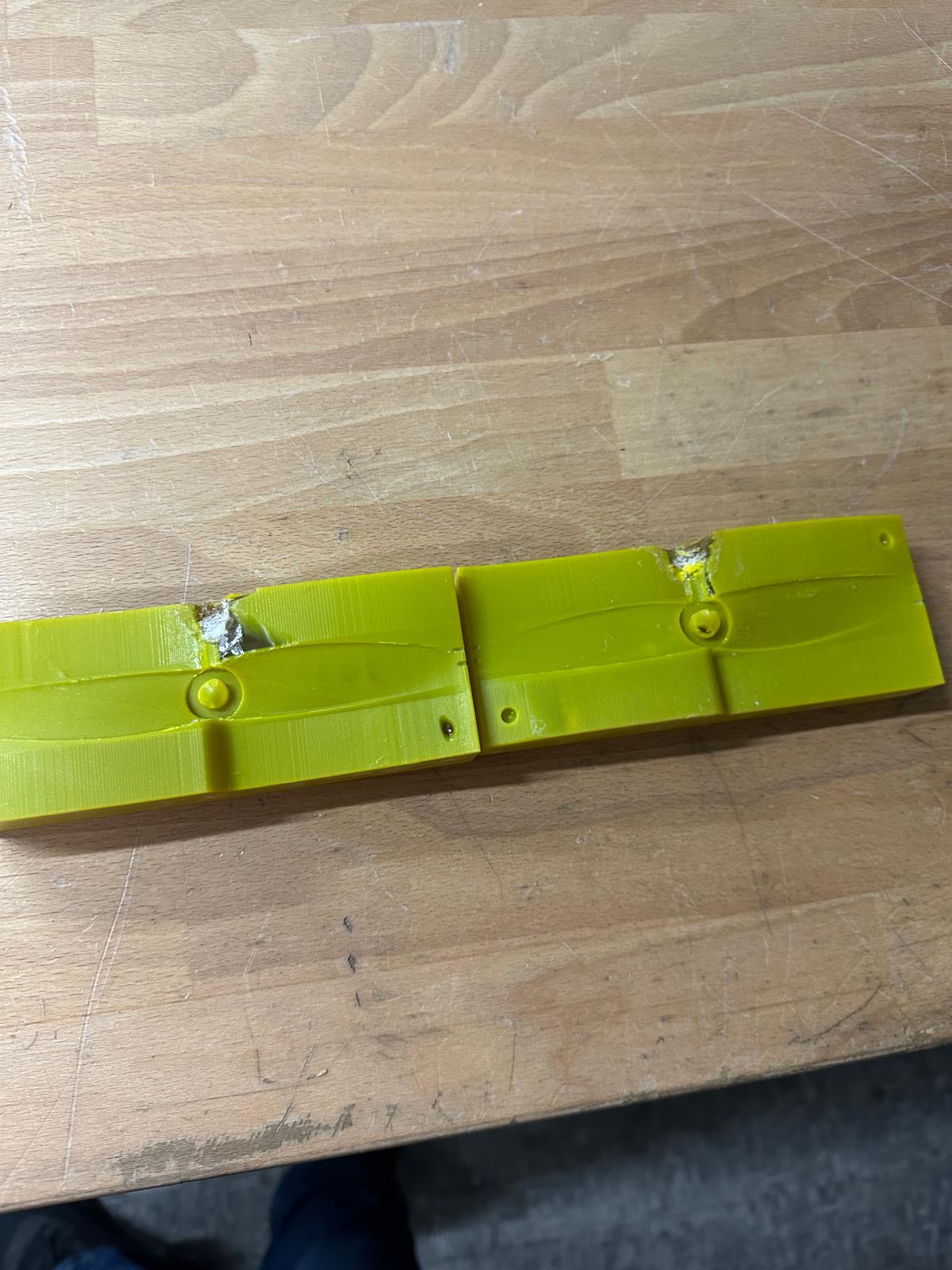

At first a BZT PFE 1510PX CNC machine was demonstrated, along with a brief explanation of G-Code, the programming language used for CNC machines. Next a hands-on introduction to a trotec Speedy 100 laser cutter, a Proxxon PD 400 lathe and a Proxxon FF 500 milling machine followed, qualifiyng us to use these machines on our own. Finally we were shown injection molding of a plastic into a resin-printed mold, where the importance of high quality molds became forcefully clear, due to the cast failing because of a too badly worn mold.

Additionally, a short introduction to Inkscape was given for the creation of our own design for the laser cutter.

CNC Mill Demonstartion

Manual Mill

Manual Lathe

Setup for Injection Molding

Well used Mold

Laser Cutting and Engraving: Demo and First Steps

For more laser cutting and engraving, please take a look at the tray for the Robo Dog project!